Net Zero Solutions

At the forefrontInnovationDevelopmentResesarch

R+D+i

Net Zero Solutions

Collaboration with the Heat Transfer Technology Center (CTTC) of the Polytechnic University of Catalonia-BarcelonaTech (UPC). This collaboration has focused on the definition of thermal accumulators with the use of molten salts.

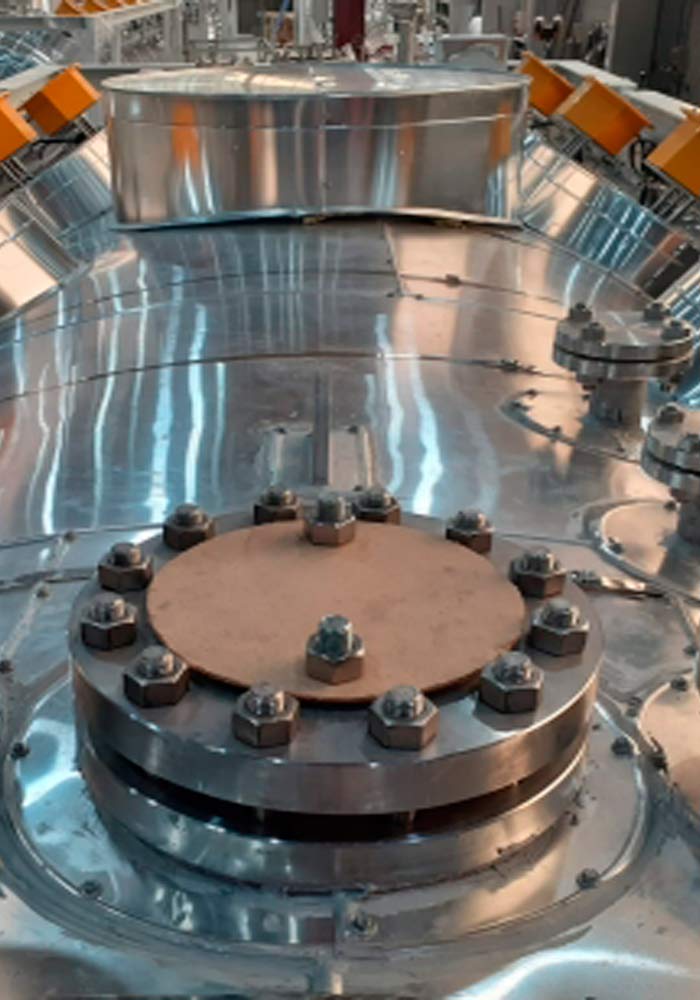

Thermal Battery

The work carried out, both in technological design and experimental aspects, allows us to improve, innovate and develop solutions according to the industrial application and in the different parts of the thermal package: accumulator, heaters, exchangers, insulation, tracing, etc.

The CTTC has extensive experience, both simulation and experimental, in the sector of solar thermal power plants (CSP), and has developed advanced computer codes for the detailed simulation of double-tank accumulation systems and thermocline systems, as well as thermochemical accumulation. Together with them we have collaborated in several initiatives in projects for CDTI and IDAE.

Núcleo Batería Térmica para generación de energía

Innovation in heat tracing

LL and ULL technology

Our range of Longline heating cables offers the advantage of being able to use long circuit lengths. Three phase Longline heating cables typically only require power supply points at intervals of several kilometers.

As a result, the number of electricity supply points required is drastically reduced and can mean significant CAPEX savings.

-

- Benefits: Circuits up to 50 kilometers long

- Constant power throughout the unit

- Easy installation in convenient lengths

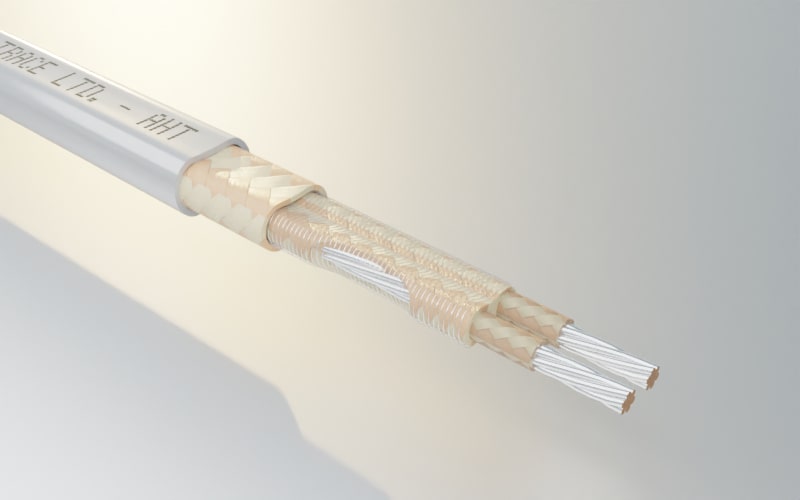

AHT technology

Our AHT cables are constant power heating cables that can work up to 500ºC, this gives them the ability to cover a wider range of applications. Its structure equipped with an aluminum cover gives it a great guarantee against thermal stress and mechanical protection.

These cables can replace MI, depending on the application and thermal needs, but with the great advantage of being a coiled cable that can be applied quickly and easily. The AHT cable family is offered in a wide range of powers ranging from 15 to 150 W/m, so we can provide a solution to almost all thermal needs.

Tubing Bundle

Proheat has extensive experience in designing and manufacturing its own tubing bundles. These heat-tracing systems are specialized for instrumentation tubing heat tracing, and their advantage is that tubing, heat tracing and insulation are incorporated into a single product, giving a unique and total solution.

The different insulation and tracing alternatives that are studied and analyzed by our engineering and a specific product is designed for the client's needs.

The Proheat Tubing Bundle, studied from thermal needs, allows us to be more precise, more effective and more efficient throughout the design, manufacturing and supply process.

Our Tubing Bundle, is studied from the thermal needs, it is more precise, more effective and more efficient in the entire design, manufacturing and supply process.